Get the free Polyethylene Piping Systems Field Manual for Municipal Water ... - plasticpipe

Show details

Polyethylene Piping Systems

Field Manual

for

Municipal Water

Applications

M&I Division

2009 Edition

Page 1 of 88

Table of Contents

Table of Contents ....................................................................................2

PE

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

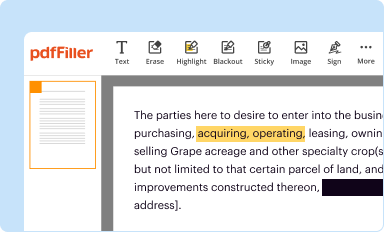

Edit your polyethylene piping systems field form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

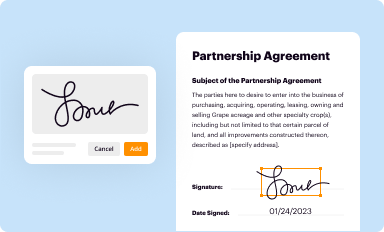

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your polyethylene piping systems field form via URL. You can also download, print, or export forms to your preferred cloud storage service.

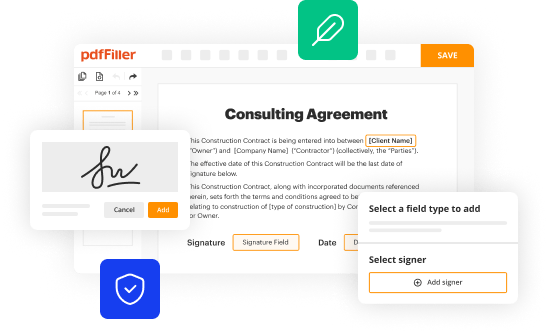

How to edit polyethylene piping systems field online

Here are the steps you need to follow to get started with our professional PDF editor:

1

Sign into your account. It's time to start your free trial.

2

Prepare a file. Use the Add New button. Then upload your file to the system from your device, importing it from internal mail, the cloud, or by adding its URL.

3

Edit polyethylene piping systems field. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Get your file. Select your file from the documents list and pick your export method. You may save it as a PDF, email it, or upload it to the cloud.

With pdfFiller, it's always easy to work with documents.

How to fill out polyethylene piping systems field

How to fill out polyethylene piping systems field:

01

Start by assessing the needs and requirements of the project or application. Determine the desired length, diameter, and type of polyethylene pipe required.

02

Calculate the amount of pipe needed, taking into account factors such as pressure rating, flow rate, and potential expansion or contraction.

03

Choose the appropriate fittings and connectors for the polyethylene piping system. This may include couplings, elbows, tees, valves, and adapters. Ensure that they are compatible with the pipe material and are suitable for the intended application.

04

Prepare the installation area by clearing any obstructions, ensuring proper drainage, and complying with any applicable regulations or guidelines.

05

Install the polyethylene pipe, following the manufacturer's instructions and industry best practices. This may involve cutting the pipe to the desired length, joining sections using fusion or mechanical methods, and securing the fittings tightly.

06

Test the integrity of the polyethylene piping system by conducting appropriate pressure and leak tests. This will help ensure that the system is properly installed and capable of withstanding the intended operating conditions.

07

Once the polyethylene piping system is successfully installed and tested, perform any necessary pressure adjustments, flow calibrations, or system flushes to optimize its performance.

08

Regularly inspect and maintain the polyethylene piping system to prevent any potential issues or failures. This may include monitoring for leaks, repairing or replacing damaged components, and ensuring proper alignment and support of the pipes.

Who needs polyethylene piping systems field:

01

Industries and sectors that require the transportation of fluids, gases, or other materials, such as water treatment plants, oil and gas refineries, chemical processing plants, and agricultural irrigation systems.

02

Construction and infrastructure projects that involve the installation of underground or aboveground pipelines, such as water supply networks, sewage systems, gas distribution lines, and telecommunications infrastructure.

03

Residential and commercial buildings that require plumbing systems, including water supply lines, drainage systems, and heating or cooling systems.

04

Environmental and remediation projects that involve the containment or management of hazardous substances, such as landfill liners, underground storage tank systems, and remediation systems for contaminated soil or groundwater.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is polyethylene piping systems field?

Polyethylene piping systems field refers to the area of work that involves the installation, maintenance, and repair of pipes made from polyethylene, a type of plastic polymer commonly used in plumbing and industrial applications.

Who is required to file polyethylene piping systems field?

There is no specific requirement to file for the polyethylene piping systems field. However, individuals or companies engaged in polyethylene piping systems work are responsible for ensuring compliance with relevant regulations and standards.

How to fill out polyethylene piping systems field?

Filling out the polyethylene piping systems field involves documenting all relevant information related to the installation, maintenance, and repair of polyethylene pipes. This includes recording details such as the location of the pipes, the types of fittings used, and any inspections or testing conducted.

What is the purpose of polyethylene piping systems field?

The purpose of the polyethylene piping systems field is to ensure the safe and efficient installation, maintenance, and operation of polyethylene pipe systems. It aims to prevent leaks, failures, and other issues that could result in health and safety hazards or costly repair work.

What information must be reported on polyethylene piping systems field?

The information that must be reported on the polyethylene piping systems field includes details about the project or task being performed, the materials and equipment used, any tests or inspections conducted, and any incidents or issues encountered during the work.

When is the deadline to file polyethylene piping systems field in 2023?

The deadline to file for the polyethylene piping systems field in 2023 will depend on the specific requirements and regulations set by the relevant authorities or governing bodies. It is recommended to consult the local regulations or industry guidelines for the specific deadline.

What is the penalty for the late filing of polyethylene piping systems field?

The penalty for the late filing of the polyethylene piping systems field may vary depending on the jurisdiction and governing bodies. It is advisable to refer to the applicable regulations or consult with the relevant authorities to determine the specific penalties and consequences for late filing.

How can I send polyethylene piping systems field for eSignature?

When your polyethylene piping systems field is finished, send it to recipients securely and gather eSignatures with pdfFiller. You may email, text, fax, mail, or notarize a PDF straight from your account. Create an account today to test it.

Where do I find polyethylene piping systems field?

It's simple with pdfFiller, a full online document management tool. Access our huge online form collection (over 25M fillable forms are accessible) and find the polyethylene piping systems field in seconds. Open it immediately and begin modifying it with powerful editing options.

How do I edit polyethylene piping systems field online?

With pdfFiller, it's easy to make changes. Open your polyethylene piping systems field in the editor, which is very easy to use and understand. When you go there, you'll be able to black out and change text, write and erase, add images, draw lines, arrows, and more. You can also add sticky notes and text boxes.

Fill out your polyethylene piping systems field online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.