Now, the industry is changing the way it works. It is now not only about gluing but also about a range of techniques and materials that are now incorporated into the process. This is exactly where the new generation of welding technology comes in. We have developed and introduced, by far, the most advanced welding modalities in the world today. These are the “electroplate” welding modalities, in which a laser energy is transmitted as a beam within the material from a high-powered laser. Through an electroplate welding, it is possible to create joint shapes with extreme tolerance. Our new electroplate welding modalities enable to make the joint shape of the joints so accurate that it can actually be felt by a human hand. We take pride in having pioneered and brought the idea to a successful commercialization stage with our “electroplate” electroplate welding technology. A range of cutting edge techniques are also included: electroplate weld technology, using a continuous stream of positive and negative ions from an externally directed laser (an electric arc) to bond the material to the joint; electroplate weld technology, in which an electromagnetic beam is used for welding, which is different from conventional electron PLA because the arc can be driven even closer to the joint than normal PLA; electroplate welding technology, based on the use of electrons for welding; electroplate welding technology, where a beam of positive ions from an external laser beam are emitted from the beam as the material is welded by two electrodes.

Get the free Laser transmission welding at any wavelength. - basf

Show details

Contact worldwide Asia BASF East Asia Regional Headquarters Ltd. 45/F, Sardine House No. 1 Conn aught Place Central Hong Kong Tel.: +852 2731 4312 Fax: +852 2734 9670 Aesthetics and durability Laser

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

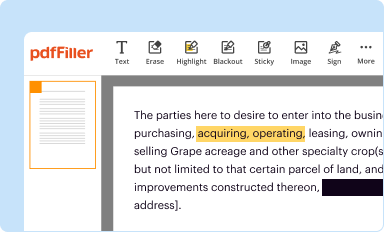

Edit your laser transmission welding at form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your laser transmission welding at form via URL. You can also download, print, or export forms to your preferred cloud storage service.

How to edit laser transmission welding at online

To use our professional PDF editor, follow these steps:

1

Sign into your account. In case you're new, it's time to start your free trial.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit laser transmission welding at. Add and change text, add new objects, move pages, add watermarks and page numbers, and more. Then click Done when you're done editing and go to the Documents tab to merge or split the file. If you want to lock or unlock the file, click the lock or unlock button.

4

Save your file. Select it from your records list. Then, click the right toolbar and select one of the various exporting options: save in numerous formats, download as PDF, email, or cloud.

pdfFiller makes working with documents easier than you could ever imagine. Try it for yourself by creating an account!

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is laser transmission welding at?

Laser transmission welding is a process in which two or more materials are joined together using a laser beam to create a strong and durable weld. The laser beam is focused on the join line, heating and melting the materials, which then fuse together and solidify to form the weld.

Who is required to file laser transmission welding at?

The requirement to file laser transmission welding forms may vary depending on the jurisdiction and specific regulations. Generally, it is the responsibility of the manufacturer or company using laser transmission welding equipment to file the necessary forms and documentation with the relevant regulatory authorities.

How to fill out laser transmission welding at?

To fill out a laser transmission welding form, you will typically need to provide detailed information about the equipment used, the materials being welded, safety measures in place, and any certifications or qualifications of the operator. The specific requirements may differ based on the jurisdiction and applicable regulations. It is recommended to refer to the official guidelines or consult with regulatory authorities for accurate and up-to-date instructions on filling out the form.

What is the purpose of laser transmission welding at?

The purpose of laser transmission welding is to create strong and reliable joints between different materials through the use of laser technology. This welding process is often used in various industries, such as automotive, electronics, medical, and more, to join components and parts together with precision and efficiency. The goal is to achieve high-quality welds that meet the required standards and ensure the integrity of the final product.

What information must be reported on laser transmission welding at?

The information required to be reported on a laser transmission welding form may include details about the equipment used (such as laser power, wavelength, and type), the materials being welded, safety measures in place, operating procedures, certifications or qualifications of the operator, and any other relevant information specified by the regulatory authorities.

When is the deadline to file laser transmission welding at in 2023?

The specific deadline for filing laser transmission welding forms in 2023 will depend on the jurisdiction and applicable regulations. It is crucial to refer to the official guidelines or consult with the relevant regulatory authorities to determine the exact deadline and ensure compliance with the filing requirements.

What is the penalty for the late filing of laser transmission welding at?

The penalty for the late filing of laser transmission welding forms may vary depending on the jurisdiction and specific regulations. It is advisable to refer to the official guidelines or consult with the relevant regulatory authorities to understand the penalties or consequences associated with late filing. Taking timely action to comply with the filing requirements can help avoid any potential penalties or legal issues.

How can I edit laser transmission welding at from Google Drive?

pdfFiller and Google Docs can be used together to make your documents easier to work with and to make fillable forms right in your Google Drive. The integration will let you make, change, and sign documents, like laser transmission welding at, without leaving Google Drive. Add pdfFiller's features to Google Drive, and you'll be able to do more with your paperwork on any internet-connected device.

How can I get laser transmission welding at?

The premium subscription for pdfFiller provides you with access to an extensive library of fillable forms (over 25M fillable templates) that you can download, fill out, print, and sign. You won’t have any trouble finding state-specific laser transmission welding at and other forms in the library. Find the template you need and customize it using advanced editing functionalities.

How can I fill out laser transmission welding at on an iOS device?

Install the pdfFiller iOS app. Log in or create an account to access the solution's editing features. Open your laser transmission welding at by uploading it from your device or online storage. After filling in all relevant fields and eSigning if required, you may save or distribute the document.

Fill out your laser transmission welding at online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.