Get the free VALVOLE DI SICUREZZA CARICATE A MOLLA

Show details

VALVE DI SICUREZZA CARICATURE A MOLLY Spring Loaded Safety Valves 1 THE COMPANY LA SOCIETY La TAI Milano, sonata new 1959, costruisce fin DAL 1962 val vole DI sicurezza per industrial in genre e,

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

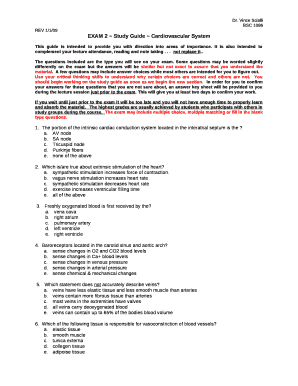

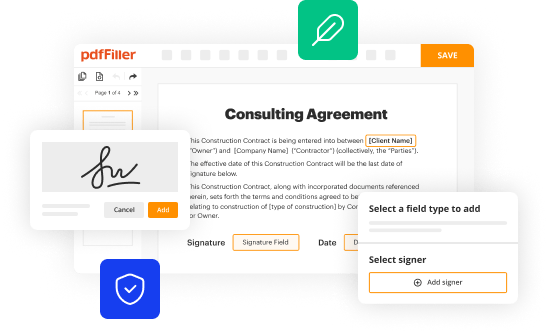

Edit your valvole di sicurezza caricate form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

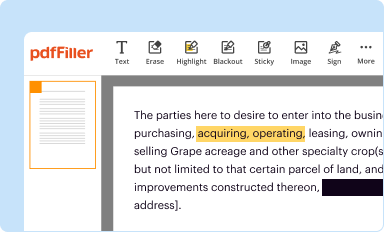

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

Share your form instantly

Email, fax, or share your valvole di sicurezza caricate form via URL. You can also download, print, or export forms to your preferred cloud storage service.

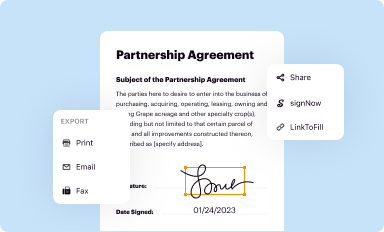

Editing valvole di sicurezza caricate online

To use our professional PDF editor, follow these steps:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Prepare a file. Use the Add New button to start a new project. Then, using your device, upload your file to the system by importing it from internal mail, the cloud, or adding its URL.

3

Edit valvole di sicurezza caricate. Replace text, adding objects, rearranging pages, and more. Then select the Documents tab to combine, divide, lock or unlock the file.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

How to fill out valvole di sicurezza caricate

How to fill out valvole di sicurezza caricate:

01

Start by gathering all the necessary equipment, such as the valve, pressure gauge, and any tools required for installation.

02

Ensure that the system is depressurized before proceeding with the filling process. This can be done by turning off the power source and releasing any remaining pressure.

03

Carefully inspect the valve to ensure it is clean and free from any debris or damage. If necessary, clean the valve using a mild detergent and a soft cloth.

04

Attach the pressure gauge to the valve, ensuring a secure connection. This will allow you to monitor the pressure during the filling process.

05

Slowly open the valve using the recommended method, whether it is a lever or a knob. Pay attention to any instructions provided by the manufacturer regarding the proper technique for opening the valve.

06

Monitor the pressure gauge closely as you gradually fill the valve. Take note of the recommended pressure range for the specific application to ensure proper operation.

07

Once the valve is filled to the desired pressure, close the valve using the recommended method. Again, refer to any instructions provided by the manufacturer for the proper technique.

08

Double-check the valve to ensure it is closed securely and no leaks are present. This may involve visually inspecting the valve or using a leak detection solution.

09

Finally, record the filling process in any necessary documentation or maintenance logs for future reference.

Who needs valvole di sicurezza caricate:

01

Industries and factories that work with pressurized systems require valvole di sicurezza caricate to ensure the safe and reliable operation of their equipment.

02

Power plants, oil refineries, chemical processing plants, and manufacturing facilities are some examples of industries that commonly use valvole di sicurezza caricate to protect against excessive pressure build-up.

03

Valvole di sicurezza caricate are also essential in HVAC systems, where they help regulate pressure in heating, cooling, and ventilation equipment.

04

Different types of machinery, such as boilers, pumps, and compressors, often rely on valvole di sicurezza caricate to prevent potential damage caused by overpressure.

05

Even residential buildings with plumbing systems may utilize valvole di sicurezza caricate to maintain safe pressure levels in the water supply.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is valvole di sicurezza caricate?

Valvole di sicurezza caricate, anche conosciute come valvole di sicurezza pre-impostate o valvole di sicurezza calibrate, sono dispositivi di sicurezza utilizzati per proteggere sistemi o apparecchiature da sovrappressioni o sovratemperature potenzialmente pericolose. Queste valvole sono regolate in modo da aprire automaticamente quando la pressione o la temperatura superano una determinata soglia preimpostata, rilasciando il fluido o il gas in eccesso e impedendo il superamento dei limiti di sicurezza. In questo modo, le valvole di sicurezza caricate contribuiscono a prevenire danni, malfunzionamenti o situazioni pericolose all'interno dei sistemi o delle apparecchiature.

How to fill out valvole di sicurezza caricate?

To fill out caricate safety valves, you will need to follow these steps:

1. Ensure that you have the appropriate equipment and tools such as gloves, safety glasses, and a pressure gauge.

2. Determine the pressure rating and type of the safety valve based on the system requirements.

3. Shut off the flow of the fluid or gas into the system and depressurize it completely.

4. Remove the safety valve from its installation point or access point using the appropriate tools.

5. Inspect the valve for any signs of damage or wear. Replace it if necessary.

6. Check the valve's manufacturer's instructions or datasheet for specific filling guidelines. Different valves have different methods for loading, depending on their design and purpose.

7. Typically, you will need to load the valve with the proper weight or spring tension to match the system's pressure requirements. Use a calibrated weight or adjust the spring tension accordingly.

8. Carefully insert the weight or adjust the spring tension according to the manufacturer's instructions. Take caution not to overtighten or overload the valve.

9. Reinstall the safety valve back into its original position or access point, ensuring a secure fit.

10. Turn on the flow of fluid or gas into the system, and monitor the pressure gauge to verify that the valve is functioning correctly and relieving pressure at the desired level.

11. Conduct regular maintenance and inspections of the safety valve to ensure it remains in good working condition.

Note: It is always recommended to consult the valve's manufacturer instructions or seek professional assistance for specific guidance related to your valve model and application.

What is the purpose of valvole di sicurezza caricate?

Valvole di sicurezza caricate, or loaded safety valves in English, serve the purpose of protecting a system or equipment from potentially dangerous levels of pressure. These valves are installed in various industrial applications, such as steam boilers, pipelines, pressure vessels, or any system that operates under high pressure.

The primary function of a loaded safety valve is to relieve excess pressure by opening and discharging the fluid or gas to a safe location when the system pressure exceeds a designated setpoint. This prevents the equipment from getting damaged or failing due to excessive pressure, which could lead to accidents, explosions, or other hazardous situations.

The valves are designed to automatically open at a predetermined pressure and reclose once the pressure is reduced to a safe level. They are typically spring-loaded and calibrated to the specific pressure requirements of the system they are protecting. The spring force determines the pressure at which the valve will open and relieve the pressure.

In addition to providing overpressure protection, loaded safety valves also play a role in maintaining system efficiency and preventing unwanted shutdowns or damage. They ensure that the pressure is regulated within acceptable limits, allowing the system to operate safely and reliably.

Overall, the purpose of valvole di sicurezza caricate is to protect equipment, personnel, and the environment by controlling and relieving excess pressure, thereby preventing potentially hazardous situations.

What information must be reported on valvole di sicurezza caricate?

The information that must be reported on safety valves includes:

1. Manufacturer's name or trademark: The name or trademark of the company that manufactures the safety valve must be clearly indicated.

2. Valve type and size: The type of valve (e.g., spring-loaded, pilot-operated) and its size (e.g., DN, inches) must be reported for easy identification.

3. Set pressure: The pressure at which the safety valve is set to open and relieve excess pressure must be clearly stated.

4. Flow capacity: The maximum capacity of the valve to release fluid or gas, usually expressed in terms of flow rate (e.g., kg/h, lb/h).

5. Material of construction: The materials used in constructing the safety valve must be specified, ensuring compatibility with the fluid or gas it will handle.

6. Inlet and outlet connections: The type and size of the connections for the inlet and outlet ports of the valve (e.g., threaded, flanged) should be reported for proper installation.

7. Certification or compliance marks: Any certifications or compliance marks from recognized standards organizations (e.g., ASME, PED) should be indicated to confirm the valve's compliance with relevant safety and quality standards.

8. Serial number and production date: Each safety valve should be assigned a unique serial number, along with the manufacturing date or lot number, for traceability and quality control purposes.

9. Maintenance and testing information: Instructions on how to maintain, repair, and test the safety valve should be provided, including recommended intervals for regular inspections and certifications.

10. Additional information: Any additional information relevant to the operation, maintenance, or installation of the safety valve may also be included in the report.

What is the penalty for the late filing of valvole di sicurezza caricate?

The penalty for the late filing of "Valvole di sicurezza caricate" (safety valves loaded) may vary depending on the specific jurisdiction and applicable regulations governing valve safety in that location. It is recommended to consult the local regulatory authority or legal expert to determine the specific penalty for late filing in your region.

How do I modify my valvole di sicurezza caricate in Gmail?

valvole di sicurezza caricate and other documents can be changed, filled out, and signed right in your Gmail inbox. You can use pdfFiller's add-on to do this, as well as other things. When you go to Google Workspace, you can find pdfFiller for Gmail. You should use the time you spend dealing with your documents and eSignatures for more important things, like going to the gym or going to the dentist.

How do I fill out the valvole di sicurezza caricate form on my smartphone?

The pdfFiller mobile app makes it simple to design and fill out legal paperwork. Complete and sign valvole di sicurezza caricate and other papers using the app. Visit pdfFiller's website to learn more about the PDF editor's features.

How do I complete valvole di sicurezza caricate on an Android device?

Complete your valvole di sicurezza caricate and other papers on your Android device by using the pdfFiller mobile app. The program includes all of the necessary document management tools, such as editing content, eSigning, annotating, sharing files, and so on. You will be able to view your papers at any time as long as you have an internet connection.

Fill out your valvole di sicurezza caricate online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.