Get the free Welding Technology Pipe - roanokechowan

Show details

Alabama Aviation and Technical College, Diploma in Structural & Pipe Welding. Educational Philosophy: Insert instructor's educational philosophy here.

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

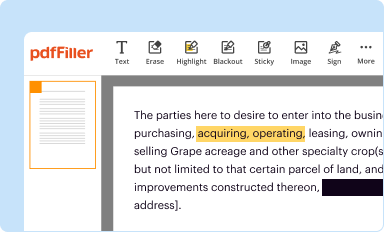

Edit your welding technology pipe form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

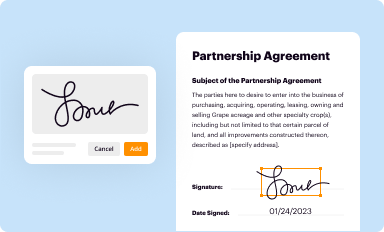

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

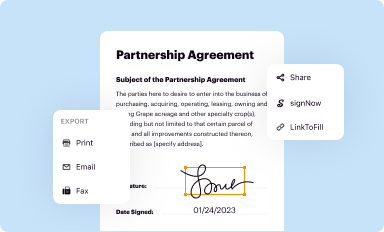

Share your form instantly

Email, fax, or share your welding technology pipe form via URL. You can also download, print, or export forms to your preferred cloud storage service.

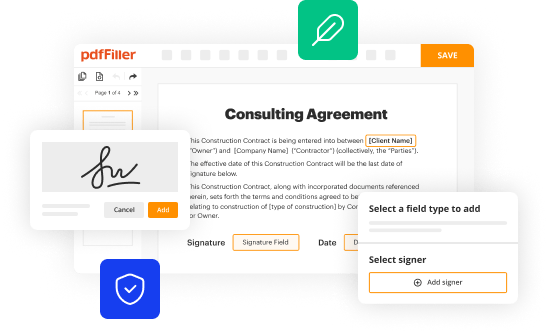

Editing welding technology pipe online

To use our professional PDF editor, follow these steps:

1

Log in. Click Start Free Trial and create a profile if necessary.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit welding technology pipe. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

It's easier to work with documents with pdfFiller than you could have believed. You can sign up for an account to see for yourself.

How to fill out welding technology pipe

To fill out a welding technology pipe, follow these steps:

01

Prepare the welding technology pipe by ensuring it is clean and free from any contaminants, such as dirt or oil.

02

Select the appropriate welding process and filler material based on the type of pipe and desired joint strength.

03

Set up the welding equipment, including the power source, electrode or filler wire, and gas supply if needed.

04

Position the welding torch or electrode holder at the starting point of the weld joint, ensuring a proper angle and distance from the pipe.

05

Initiate the welding process by striking an arc or initiating the flow of current, depending on the welding technique being used.

06

Begin welding by moving the welding torch or electrode in a controlled motion along the joint, ensuring proper heat input and fusion with the base material.

07

Maintain a consistent welding speed and weave pattern to achieve a uniform weld bead and minimize distortion.

08

Continuously monitor the welding parameters, such as current, voltage, and travel speed, to ensure the desired quality of the weld.

09

Once the welding is completed, inspect the weld joint for any defects or imperfections and perform any required post-weld processes, such as grinding or cleaning.

10

Finally, document the welding process by recording the parameters used, the type of filler material, and any other relevant information for future reference.

As for who needs welding technology pipe, various industries and individuals rely on this technology. It is essential for industries involved in construction, manufacturing, oil and gas, plumbing, automotive, and many more. Welding technology pipes are commonly used in applications such as pipeline systems, structural fabrication, equipment assembly, and repairs. Additionally, individuals with welding skills may require welding technology pipes for personal projects or hobbies, such as building custom furniture or constructing metal sculptures.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is welding technology pipe?

Welding technology pipe is a process used to join two metal pieces together using heat and/or pressure.

Who is required to file welding technology pipe?

Those individuals or companies who are involved in welding technology pipe process are required to file.

How to fill out welding technology pipe?

To fill out welding technology pipe, one must provide information about the welding process, materials used, welding techniques, etc.

What is the purpose of welding technology pipe?

The purpose of welding technology pipe is to create a strong and durable joint between two metal pieces.

What information must be reported on welding technology pipe?

Information such as welder qualifications, welding procedures, materials used, inspection results, etc. must be reported on welding technology pipe.

When is the deadline to file welding technology pipe in 2023?

The deadline to file welding technology pipe in 2023 is on December 31st, 2023.

What is the penalty for the late filing of welding technology pipe?

The penalty for the late filing of welding technology pipe may include fines or other consequences as per regulations.

How can I manage my welding technology pipe directly from Gmail?

The pdfFiller Gmail add-on lets you create, modify, fill out, and sign welding technology pipe and other documents directly in your email. Click here to get pdfFiller for Gmail. Eliminate tedious procedures and handle papers and eSignatures easily.

How can I get welding technology pipe?

The pdfFiller premium subscription gives you access to a large library of fillable forms (over 25 million fillable templates) that you can download, fill out, print, and sign. In the library, you'll have no problem discovering state-specific welding technology pipe and other forms. Find the template you want and tweak it with powerful editing tools.

Can I edit welding technology pipe on an iOS device?

Create, modify, and share welding technology pipe using the pdfFiller iOS app. Easy to install from the Apple Store. You may sign up for a free trial and then purchase a membership.

Fill out your welding technology pipe online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.