Get the free Solid Carbide, Milling Cuters, Step Drills

Show details

LEISTRITZ PRODUKTIONSTECHNIK GmbH L2 L3 D2 EF ER EW Solid Carbide Milling Cutters Step Drills 1 Fraser prospect en must. Indy 1 20.04.11 15:00 Lasting is supplying solid carbide end mills and solid

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

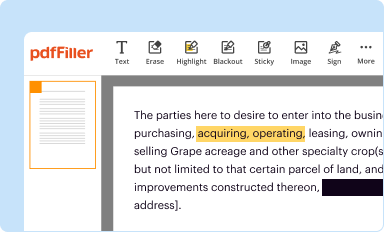

Edit your solid carbide milling cuters form online

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

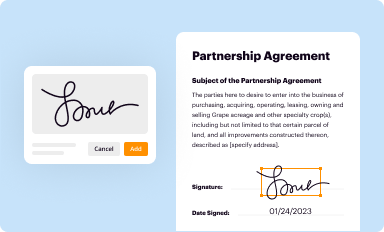

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

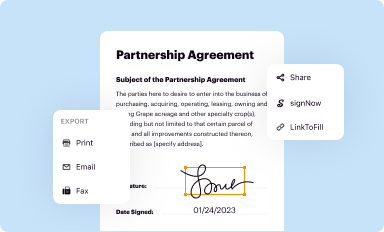

Share your form instantly

Email, fax, or share your solid carbide milling cuters form via URL. You can also download, print, or export forms to your preferred cloud storage service.

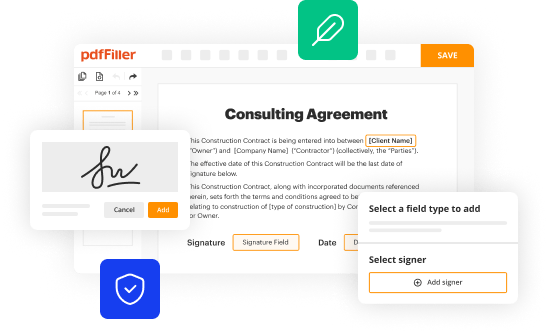

Editing solid carbide milling cuters online

Follow the guidelines below to benefit from a competent PDF editor:

1

Create an account. Begin by choosing Start Free Trial and, if you are a new user, establish a profile.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit solid carbide milling cuters. Text may be added and replaced, new objects can be included, pages can be rearranged, watermarks and page numbers can be added, and so on. When you're done editing, click Done and then go to the Documents tab to combine, divide, lock, or unlock the file.

4

Save your file. Select it in the list of your records. Then, move the cursor to the right toolbar and choose one of the available exporting methods: save it in multiple formats, download it as a PDF, send it by email, or store it in the cloud.

How to fill out solid carbide milling cuters

How to fill out solid carbide milling cutters:

01

Start by gathering the necessary materials, including the solid carbide milling cutters, a cutting oil or coolant, and any required safety equipment such as gloves or safety glasses.

02

Before filling out the milling cutters, ensure they are clean and free from any debris or contaminants. Use a brush or compressed air to remove any particles.

03

Determine the appropriate cutting oil or coolant to use based on the type of material being cut and the specific requirements of the milling operation. Consult the manufacturer's guidelines or recommendations if necessary.

04

Carefully pour or apply the cutting oil or coolant onto the milling cutters, making sure to distribute it evenly across the cutting edges and surfaces. This will help to reduce friction, heat, and tool wear during the milling process.

05

If using a liquid coolant, it may be necessary to adjust the flow rate or pressure according to the specific application. Follow the guidelines provided by the coolant manufacturer or refer to the milling machine's instructions for optimal settings.

06

Once the milling cutters are filled with the appropriate cutting oil or coolant, they are ready for use. Ensure they are securely attached to the milling machine or tool holder before starting any cutting operations.

07

Regularly inspect the milling cutters during use to ensure proper lubrication. If needed, apply additional cutting oil or coolant to maintain a consistent flow and ensure the cutters remain in good working condition.

08

After completing the milling operations, clean the milling cutters thoroughly to remove any remaining cutting oil or coolant. This will prevent build-up and maintain their performance for future use.

Who needs solid carbide milling cutters:

01

Machinists and manufacturers involved in metalworking and machining industries often require solid carbide milling cutters. These tools are specifically designed for high-speed milling operations and offer excellent cutting performance and durability.

02

Solid carbide milling cutters are commonly used in industries such as automotive, aerospace, mold and die making, and general manufacturing.

03

Hobbyists and DIY enthusiasts who work with metal or engage in precision machining may also find solid carbide milling cutters to be beneficial for their projects. These tools can help achieve precise cuts and shapes in various materials.

04

Those working with tough or abrasive materials, such as stainless steel or hardened steel, can benefit from using solid carbide milling cutters due to their hardness and wear resistance.

05

Anyone involved in milling processes that require high precision and efficiency, such as creating complex shapes, profiles, or intricate details, can greatly benefit from using solid carbide milling cutters.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is solid carbide milling cutters?

Solid carbide milling cutters are cutting tools used in milling machines to remove material from a workpiece.

Who is required to file solid carbide milling cutters?

Manufacturers, suppliers, and distributors of solid carbide milling cutters are required to file them.

How to fill out solid carbide milling cutters?

Solid carbide milling cutters are filled out by providing information such as material type, dimensions, and cutting specifications.

What is the purpose of solid carbide milling cutters?

The purpose of solid carbide milling cutters is to efficiently remove material from a workpiece during milling operations.

What information must be reported on solid carbide milling cutters?

Information such as material composition, dimensions, and cutting performance should be reported on solid carbide milling cutters.

When is the deadline to file solid carbide milling cutters in 2023?

The deadline to file solid carbide milling cutters in 2023 is December 31st.

What is the penalty for the late filing of solid carbide milling cutters?

The penalty for late filing of solid carbide milling cutters may include fines or other enforcement actions by regulatory authorities.

How can I edit solid carbide milling cuters from Google Drive?

Using pdfFiller with Google Docs allows you to create, amend, and sign documents straight from your Google Drive. The add-on turns your solid carbide milling cuters into a dynamic fillable form that you can manage and eSign from anywhere.

How can I send solid carbide milling cuters for eSignature?

When you're ready to share your solid carbide milling cuters, you can swiftly email it to others and receive the eSigned document back. You may send your PDF through email, fax, text message, or USPS mail, or you can notarize it online. All of this may be done without ever leaving your account.

How can I edit solid carbide milling cuters on a smartphone?

You can easily do so with pdfFiller's apps for iOS and Android devices, which can be found at the Apple Store and the Google Play Store, respectively. You can use them to fill out PDFs. We have a website where you can get the app, but you can also get it there. When you install the app, log in, and start editing solid carbide milling cuters, you can start right away.

Fill out your solid carbide milling cuters online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.