Get the free Instrument Manufacturing for Measuring and Testing Electricity and ... - census

Show details

Instrument Manufacturing for Measuring and Testing Electricity and Electrical Signals 1997 Issued November 1999 EC97M-3345F 1997 Economic Census Manufacturing Industry Series U.S. Department of Commerce

We are not affiliated with any brand or entity on this form

Get, Create, Make and Sign

Edit your instrument manufacturing for measuring form online

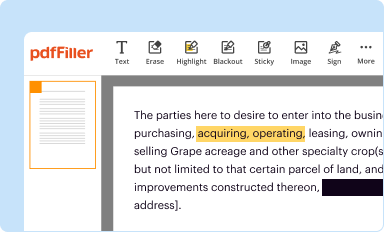

Type text, complete fillable fields, insert images, highlight or blackout data for discretion, add comments, and more.

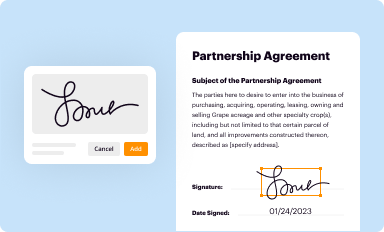

Add your legally-binding signature

Draw or type your signature, upload a signature image, or capture it with your digital camera.

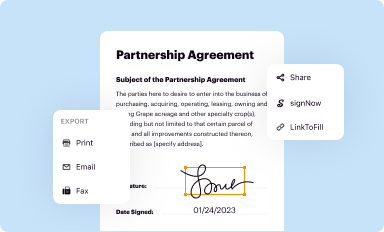

Share your form instantly

Email, fax, or share your instrument manufacturing for measuring form via URL. You can also download, print, or export forms to your preferred cloud storage service.

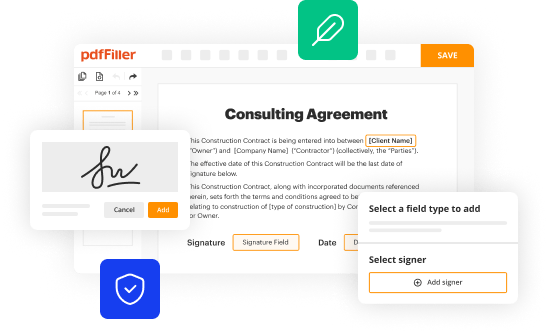

Editing instrument manufacturing for measuring online

To use the professional PDF editor, follow these steps:

1

Set up an account. If you are a new user, click Start Free Trial and establish a profile.

2

Upload a file. Select Add New on your Dashboard and upload a file from your device or import it from the cloud, online, or internal mail. Then click Edit.

3

Edit instrument manufacturing for measuring. Rearrange and rotate pages, add new and changed texts, add new objects, and use other useful tools. When you're done, click Done. You can use the Documents tab to merge, split, lock, or unlock your files.

4

Get your file. Select the name of your file in the docs list and choose your preferred exporting method. You can download it as a PDF, save it in another format, send it by email, or transfer it to the cloud.

Dealing with documents is always simple with pdfFiller. Try it right now

How to fill out instrument manufacturing for measuring

How to fill out instrument manufacturing for measuring:

01

Start by gathering all the necessary information about the instrument you are manufacturing. This includes the specific measurements it needs to be capable of making, any special features or functions it should have, and any specific materials or components that are required.

02

Next, carefully plan out the manufacturing process step by step. Consider the different stages involved, such as designing and prototyping, sourcing materials, assembly and testing. Create a detailed timeline and allocate resources accordingly.

03

Begin the manufacturing process by creating a design for the instrument. This can be done using computer-aided design (CAD) software or by hand, depending on your expertise and resources. Ensure that the design meets all the necessary specifications and requirements.

04

Once the design is finalized, start sourcing the required materials and components. This may involve reaching out to suppliers, comparing prices and quality, and ensuring timely delivery. It is important to source reliable and high-quality materials to ensure the accuracy and longevity of the instrument.

05

With the materials at hand, proceed with the manufacturing process. This may involve various techniques such as machining, cutting, welding, or assembly, depending on the complexity of the instrument. Pay close attention to detail and follow best practices to ensure optimal functionality and accuracy.

06

After the instrument is manufactured, it is crucial to thoroughly test it for accuracy and reliability. This may involve calibrating the instrument, conducting performance tests, and comparing the measurements obtained with known standards. Make any necessary adjustments or improvements based on the test results.

07

Before the instrument is ready for distribution or use, it is important to ensure compliance with applicable regulations and standards. This may include obtaining certifications or approvals from relevant authorities.

Who needs instrument manufacturing for measuring:

01

Researchers and scientists: Instrument manufacturing for measuring is crucial for researchers and scientists working in various fields such as physics, chemistry, engineering, and biology. They rely on accurate and reliable instruments to conduct experiments, gather data, and make scientific discoveries.

02

Engineers and technicians: Instrument manufacturing is essential for engineers and technicians involved in industries such as manufacturing, construction, and telecommunications. They use specialized instruments to take measurements, analyze data, and ensure the quality and safety of their work.

03

Medical professionals: Instrument manufacturing for measuring is important in the healthcare industry. Medical professionals use various instruments to measure vital signs, diagnose diseases, monitor patients, and administer treatments. Accurate and reliable instruments are crucial for providing the best possible care to patients.

04

Quality control professionals: In industries such as automotive manufacturing, aerospace, and electronics, instrument manufacturing for measuring is indispensable for quality control. Quality control professionals rely on precise instruments to ensure that products meet the required specifications and standards before they are released to the market.

05

Individuals and hobbyists: There is also a demand for simple measuring instruments among individuals and hobbyists. From DIY projects to home improvements or woodworking, accurate measuring instruments are essential for achieving precise and professional results.

In conclusion, instrument manufacturing for measuring is necessary for a wide range of industries and professionals who rely on accurate measurements for their work or hobbies. Properly filling out the manufacturing process ensures the production of high-quality instruments that meet the specific needs and requirements of the intended users.

Fill form : Try Risk Free

For pdfFiller’s FAQs

Below is a list of the most common customer questions. If you can’t find an answer to your question, please don’t hesitate to reach out to us.

What is instrument manufacturing for measuring?

Instrument manufacturing for measuring refers to the production or assembly of instruments that are used to measure various parameters like length, weight, temperature, pressure, etc.

Who is required to file instrument manufacturing for measuring?

The companies or individuals involved in the manufacturing of measuring instruments are required to file instrument manufacturing reports. This includes manufacturers, assemblers, and distributors of such instruments.

How to fill out instrument manufacturing for measuring?

To fill out instrument manufacturing for measuring, you need to gather information about the instruments manufactured, including details such as the type of instrument, quantity produced, production dates, and other relevant information. This information is then typically reported to the regulatory authority through an online or paper form, following their specific guidelines and instructions.

What is the purpose of instrument manufacturing for measuring?

The purpose of instrument manufacturing for measuring is to ensure the quality, accuracy, and compliance of the measuring instruments produced. By filing the manufacturing reports, regulatory authorities can monitor and regulate the production, distribution, and use of these instruments to protect consumers and maintain standardized measurement practices.

What information must be reported on instrument manufacturing for measuring?

Instrument manufacturing reports typically require information such as the type of instrument manufactured, production quantity, production dates, batch or serial numbers, manufacturing location, details of the manufacturer or assembler, and any relevant certifications or compliance information. The specific information required may vary depending on the regulatory requirements of the jurisdiction in which the manufacturing takes place.

When is the deadline to file instrument manufacturing for measuring in 2023?

The deadline to file instrument manufacturing for measuring in 2023 may vary depending on the jurisdiction and specific regulations. It is advised to consult the regulatory authority or relevant documentation for the exact deadline in a particular region or country.

What is the penalty for the late filing of instrument manufacturing for measuring?

The penalty for the late filing of instrument manufacturing for measuring can also vary depending on the jurisdiction and regulatory requirements. Common penalties may include fines or penalties, suspension of manufacturing licenses, and possible legal consequences. It is important to adhere to the filing deadlines to avoid any penalties or adverse legal actions.

How can I send instrument manufacturing for measuring to be eSigned by others?

Once your instrument manufacturing for measuring is complete, you can securely share it with recipients and gather eSignatures with pdfFiller in just a few clicks. You may transmit a PDF by email, text message, fax, USPS mail, or online notarization directly from your account. Make an account right now and give it a go.

How do I edit instrument manufacturing for measuring online?

The editing procedure is simple with pdfFiller. Open your instrument manufacturing for measuring in the editor, which is quite user-friendly. You may use it to blackout, redact, write, and erase text, add photos, draw arrows and lines, set sticky notes and text boxes, and much more.

How can I edit instrument manufacturing for measuring on a smartphone?

You can easily do so with pdfFiller's apps for iOS and Android devices, which can be found at the Apple Store and the Google Play Store, respectively. You can use them to fill out PDFs. We have a website where you can get the app, but you can also get it there. When you install the app, log in, and start editing instrument manufacturing for measuring, you can start right away.

Fill out your instrument manufacturing for measuring online with pdfFiller!

pdfFiller is an end-to-end solution for managing, creating, and editing documents and forms in the cloud. Save time and hassle by preparing your tax forms online.

Not the form you were looking for?

Keywords

Related Forms

If you believe that this page should be taken down, please follow our DMCA take down process

here

.