Product Cost Analysis Template Excel

What is product cost analysis template excel?

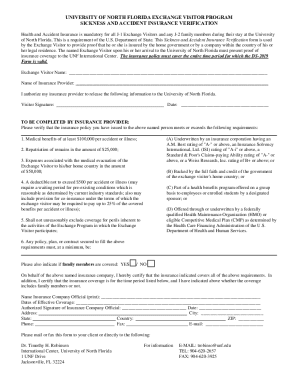

A product cost analysis template excel is a tool used to analyze the cost of producing a specific product or service. It helps businesses determine the expenses involved in manufacturing, sales, marketing, and other related activities. By using this template, companies can make informed decisions about pricing, budgeting, and overall profitability. It provides a systematic way to assess all the costs associated with a product, such as raw materials, labor, overhead, and other variable expenses. With the help of excel formulas and functions, the template calculates the total cost and provides valuable insights to optimize business operations.

What are the types of product cost analysis template excel?

There are different types of product cost analysis template excel available to cater to various industries and business needs. Some common types include:

How to complete product cost analysis template excel

Completing a product cost analysis template excel is a step-by-step process that enables businesses to gain a clear understanding of their product's expenses. Here is a guide on how to complete the template:

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.