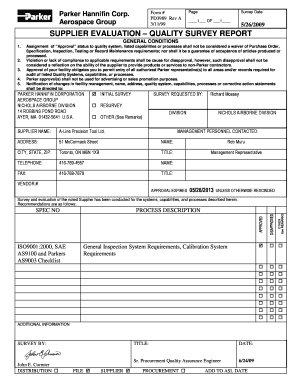

Supplier Evaluation Form Iso 9001

What is supplier evaluation form iso 9001?

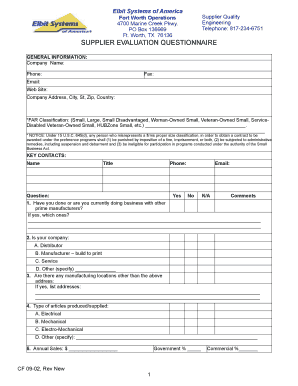

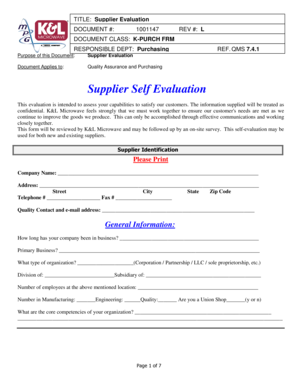

A supplier evaluation form iso 9001 is a tool used to assess and measure the performance of suppliers in relation to the ISO 9001 standard. This form helps organizations evaluate suppliers based on various criteria such as quality management systems, delivery timeliness, compliance with regulations, and customer satisfaction. By using supplier evaluation forms iso 9001, businesses can ensure the quality and reliability of their suppliers, leading to improved overall performance and customer satisfaction.

What are the types of supplier evaluation form iso 9001?

There are several types of supplier evaluation forms iso 9001 that organizations can use based on their specific needs. Some common types include: 1. Performance Evaluation Form: This form focuses on assessing suppliers' performance based on predetermined criteria such as delivery accuracy, product quality, and response time. 2. Compliance Evaluation Form: This form evaluates suppliers' compliance with ISO 9001 standards and other legal and regulatory requirements. 3. Risk Evaluation Form: This form assesses suppliers' risk levels based on factors such as financial stability, production capacity, and reputation. It is important for organizations to choose the appropriate type of supplier evaluation form iso 9001 to effectively evaluate and select suppliers.

How to complete supplier evaluation form iso 9001

Completing a supplier evaluation form iso 9001 can be done by following these steps: 1. Determine relevant evaluation criteria: Identify the key factors that need to be evaluated, such as quality management systems, delivery performance, and compliance. 2. Gather necessary information: Collect data and information about the suppliers, such as their certifications, performance records, and customer feedback. 3. Rate and score suppliers: Assign ratings or scores to suppliers based on the evaluation criteria. This can be done using a numerical scale or a rating system. 4. Analyze the results: Evaluate the scores and compare the performance of different suppliers to make an informed decision. 5. Implement improvement plans: Provide feedback and suggestions to suppliers for areas of improvement based on the evaluation results. By following these steps, organizations can effectively complete supplier evaluation forms iso 9001 and make informed decisions regarding their supplier selection process.

pdfFiller empowers users to create, edit, and share documents online. Offering unlimited fillable templates and powerful editing tools, pdfFiller is the only PDF editor users need to get their documents done.